Herringbone Paving Patterns

Herringbone Paving Patterns

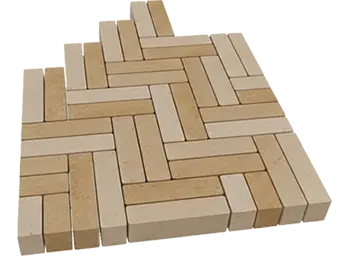

Herringbone paving patterns offer a visually striking and structurally robust solution for driveways, courtyards, and public spaces, and the subtle variations in how the pattern is arranged can dramatically influence the finished appearance. The two principal versions are the 45-degree herringbone and the 90-degree herringbone, though adaptations—such as double herringbone or framed herringbone layouts—are also common. At 45 degrees, the pattern creates a dynamic, diagonal flow that can enhance movement and visually widen a narrow space. The 90-degree pattern appears more formal and orthogonal, producing a sense of order and stability. Double herringbone, where two units are paired before the direction changes, introduces a heavier rhythm and can be effective with larger-format pavers.

Importance of dimensional

accuracy in the Pavers

Importance of dimensional

accuracy in the Pavers

Regardless of the

variation, dimensional accuracy is absolutely

critical. Herringbone relies on repeated right-angle geometry; even small

deviations in paver size—sometimes as little as 1–2 mm—accumulate across the

pattern, causing creeping joints, wandering courses, and misalignment that

becomes increasingly visible the larger the area becomes. For this reason,

concrete or sawn stone blocks with precise, consistent dimensions allow the

installer to maintain symmetry and tight control of bond lines.

Natural stone

with hand cut or cropped edges, while beautiful, can introduce irregularities

that require experienced installers to constantly adjust the pattern, trim

units, or correct for cumulative error. A poor batch of pavers, even when

nominally “to size,” can compromise the entire field, especially when laid

without borders to absorb variations.

Choosing the right pointing

option

Choosing the right pointing

option

Pointing choices also influence

the clarity and performance of the pattern. Narrow, rigid joints—possible

only when the paving units are accurately cut—emphasise the crisp geometry and

maintain the clean zig-zag visual that defines herringbone. Such joints

typically use resin or polymeric sand for stability.

Wider joints, often found

in natural stone installations, soften the pattern and can help disguise slight

inaccuracies in paver dimensions. However, inconsistent joint width is far more

visible in herringbone than in coursed patterns, so skilled, deliberate spacing

is essential.

Using perimeters and borders

Using perimeters and borders

Borders and edge restraints also play a vital role, particularly where the installer wishes to “frame” the herringbone field. A perimeter course helps contain dimensional drift and prevents lateral movement, ensuring the paving remains interlocked and visually centred. Ultimately, successful herringbone installation is a blend of precise materials, accurate alignment, attentive jointing, and careful detailing—all working together to produce a durable and beautifully ordered surface.

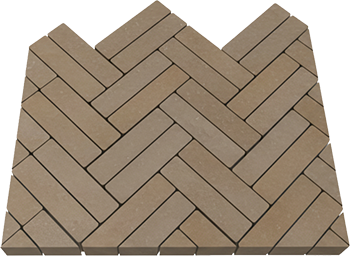

45 degree Double Herringbone Pattern using 200x50x70 pavers

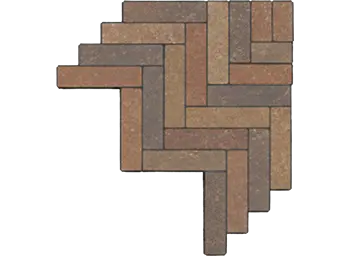

90 degree Double Herringbone Pattern using 200x50x70 pavers